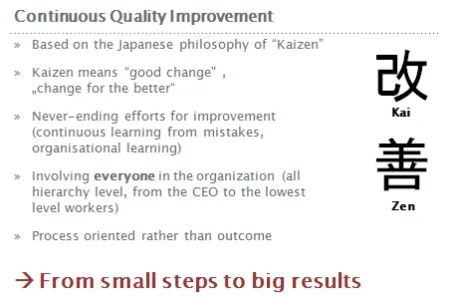

Continuous Quality Improvement is a key element of every quality management system. It is based on the Japanese philosophy Kaizen , which can be translated as “good change” (Kai = change, zen = good). Kaizen stands for “continuous improvement”, meaning an ongoing effort to identify and to abolish causes of mistakes and problems in order to improve quality and efficiency in an organization. It is a little step by step approach to make improvements rather than one spectacular innovation, but by moving forward in this way big results can be achieved. In an organization everyone, not just a selected group of people, is responsible to insure that the work is being done in the most efficient way.

The philosophy of Kaizen got introduced by W. Edwards Deming3, who supported the Japanese industry to rebuild Japan after the second world war, by giving advise how to improve quality. He recommended business leaders and engineers to concentrate on processes in an organization rather than result and to involve everyone at every stage of the process to improve deficiencies.

In the Japanese culture Kaizen is a philosophy and the foundation of their business ethnicity. Only in the late 1970s and early 1980s US and other Western companies also started to take on the concept of continuous qualtiy improvement in their business management (Helms 2006, 132).

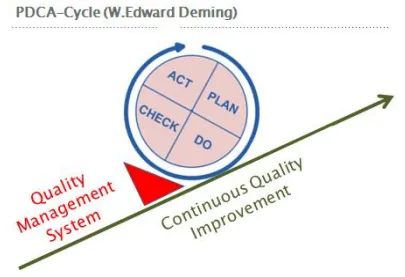

Walter A. Shewhart developed a continuous cycle of Continuous Quality Improvement. W. Edwards Deming, a disciple of Shewhart, popularized “Shewhart cycle”, so it is also often referred to as the “Deming cycle”.

The cycle includes the four steps Plan – Do – Check – Act (PDCA) (Helms 2006, 727ff).

Plan Opportunities for improvement are being identified and the change operationally planned

Do The planned change is getting tested in a small-scale study/test

Check The results of the study/test are being analyzed

Act If the results of the tested change were positive it will get implemented on a greater scale. If the results are negative a new change needs to be planned (start from the beginning of the cycle)

When the positive result is being implemented as a standard in an organization, it does not mean that improvement initiative comes to an end. With the changing of circumstances or implementing new techniques the standardized work, product or service is once again subject to further improvement. In this regard the Deming Cycle is an ongoing and never-ending process.

The effects of Continous Quality Improvement can be numerous. Some of them are mentioned below: